Technolgies & capabilities

Manufacturing

Ramsa can provide components to industries with the most demanding product requirements whether that is product shape, design, material or added value such as machining or full NDT

Engineering and Design

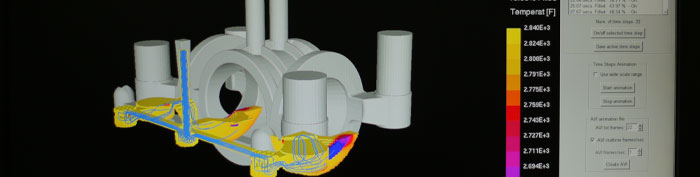

We have a dedicated team of engineers prepared to offer you their skills using the latest technology available to provide you with the best solution to your casting needs. Fabricated parts or forgings can be converted to less expensive and more functional castings. We have casting flow, solidification and stress simulation software that are used to establish the proper casting method design before going into production. By using solidification modeling we can identify problem areas before your castings are produced.

This enables us to develop the most effective and efficient manufacturing processes to reduce lead times, ensure quality and keep the processes under total control. We interface with CAD systems and can use any type of drawing files. We can also provide you with 3D drawings using our latest scanning equipment and the expertise of our engineers.

First Article castings are supplied using this agile manufacturing technology, combined with state-of-the-art CNC pattern making machines that give us an advantage when you require short lead times.

Molding

Ramsa has the ability to manufacture your casting using the molding process that best matches your requirements of surface finish, lot size, casting weight, alloy, configuration and shape.

- Ceramic Molding.

- Chemical bonded sand

- Investment Casting

- Shell

Melting

We have three induction power units of latest technology with 6 different size furnaces that give us the ability and versatility to pour castings from a few pounds up to 6000 lbs. The melting size can be as small as 80 pounds, this means you do not have to wait long for a special alloy to be poured thus reducing lead time and cost when you require single parts of a particular alloy. Our infrastructure allows for low and high production runs.

Cleaning

Our cleaning shop has all the proper tools and experienced personnel to produce your castings on a timely manner. Certified welders to ASME section IX.

Heat treating includes: Annealing; Normalizing; Normalizing and Tempering; Quenching and Tempering; and Solution Annealing.

Testing

NDT: Ramsa offers complete in-house nondestructive testing. In our staff we have qualified and certified personnel to ASNT level II and ISO 9072.

- UT

- X Ray

- Liquid penetrant

- Magnetic Particle Inspection (wet and dry)

Chemical and Mechanical Testing:

- Spectrometer (32 elements)

- Mechanical tensile

- Charpy

- Bend

- Weldability

- Hardness (Brinell and Rockwell)

- Heat Treatment Certifications and Charts

- Grain size

- Microstructure

- Corrosion

- Ferrite content

Added Value Services

We work everyday to improve. These value service are the evidence of this.

Pattern Shop

In our in house pattern shop we have the equipment, engineering and technical experience to transform your designs into reliable patterns for working castings.

Ramsa can offer you with services that include the design, layout, and fabrication of new patterns and core boxes, maintenance of existing patterns and core boxes. Patterns can be fabricated in different materials using our existing 5 axis CNC router or by traditional pattern makers with years of experience.

Machining

As a value added service, since 1995 Ramsa integrated a fully equipped CNC machine shop. We can provide you with pre and finish machined castings; paint, hydro test and some assembly can be included.

If you need further information contact us

Contact us we can help you

Aviso de privacidad | Security | Humans

Ram S.A. de C.V. Copyright © 2014 Proudly Made in Mx